Although aluminum is the easiest material to reprocess, the recycling process is complex. The recycling process happens in 5 main stages:

- Collecting

- Sorting and Cleaning

- Melting and Casting

- Rolling

- Product Cupping

Stage 1: Collecting

Collecting happens from two sides:

- The consumer deposits aluminium cans, foil, and other aluminum food and drink packaging at kerbsides, can banks, or cash for cans centres.

- Agents from local councils and waste management companies collect the large quantities of aluminium cans and other aluminum recyclables from the deposit points and bring them to the treatment plant.

Stage 2: Sorting and Cleaning

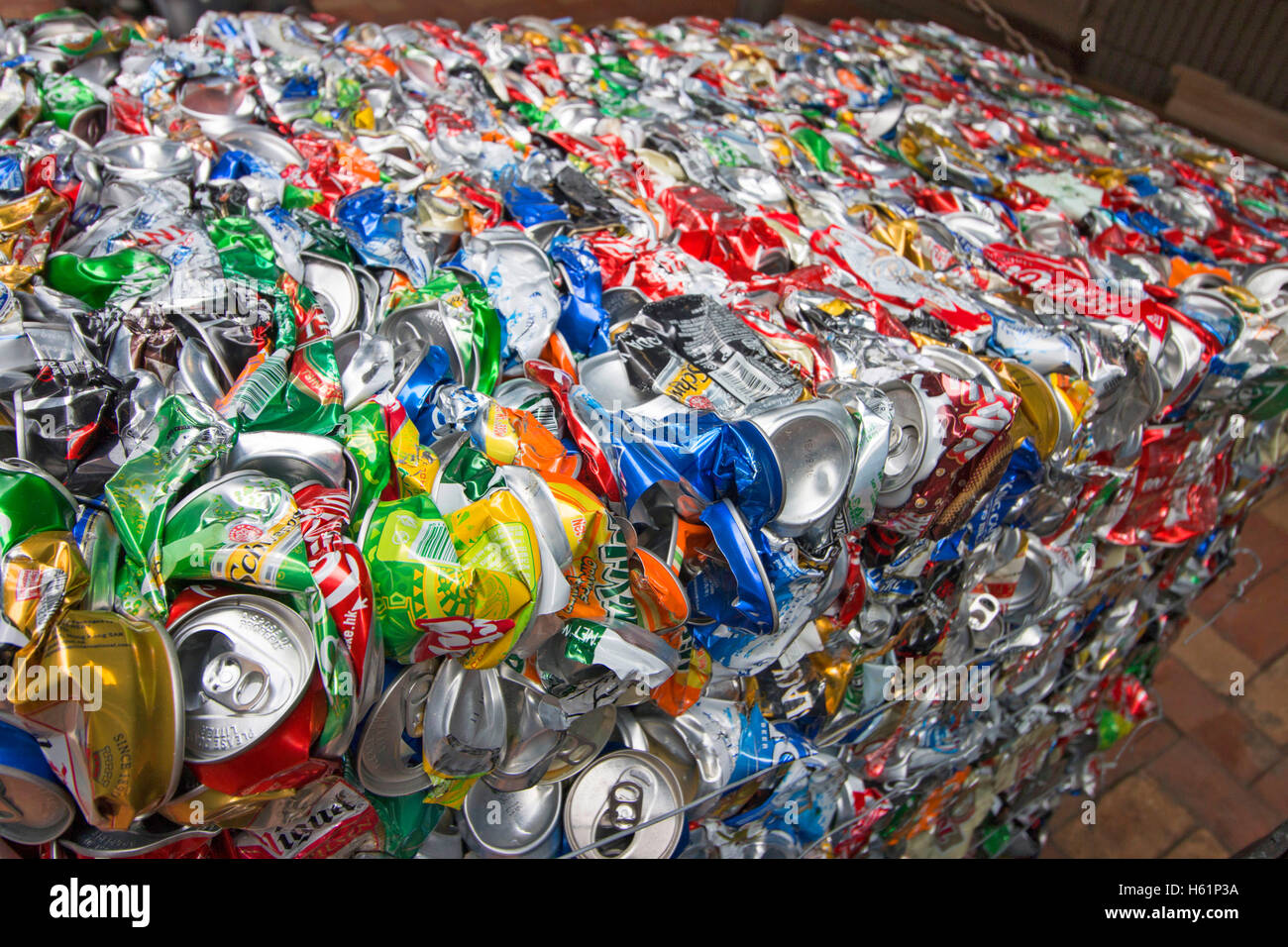

Aluminum cans and packaging brought to the materials recovery facility (MRF) are prepared for the recycling process. They are sorted, flattened, and compressed into bales. The aluminium cans are then shredded into small pieces. The pieces are washed, and hot air is passed through them to remove any decoration.

Stage 3: Melting and Casting

The cleaned aluminum shreds are melted at extremely high temperatures (around 750°C). The molten aluminium flows into moulds, where it is cast into large blocks known as ingots.

Stage 4: Rolling

Aluminum ingots are transferred to a rolling mill and rolled out into sheets. The thickness of the metal sheets is determined by the type of product they will be used to make.

Stage 5: Product Cupping

Aluminum sheets are lubricated and cupped or formed into different products including drink cans, food packaging containers, and chocolate wrappings.

The products are then treated with lacquer, a protective coating from resin that prevents the food and drink in aluminum containers from reacting with the metal. Lacquer also creates the base for decorating aluminum products such as the coca cola cans you see daily.

Ready aluminium products are then sent to manufacturing firms for filling. Products like food packaging containers and aluminum foil are sent to supermarkets and distribution stores.

Reviews

There are no reviews yet.